Tribotechnical laboratory

We perform tribological research. We issue a conclusion.

Wear resistance test for friction pairs of materials

Determination of friction coefficient

Resource testing materials friction pairs

Selection of materials for friction pairs for different operating conditions

Our equipment allows to carry out tribological tests to maximize the actual operating conditions in various environments.

Our equipment

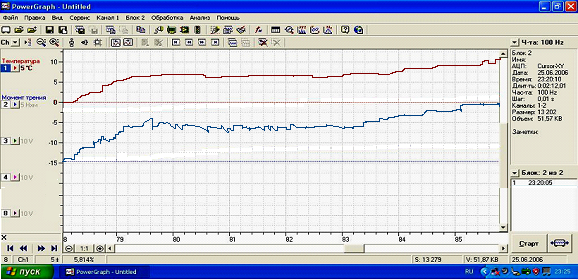

SMC-2 modified friction machine

Basic test (determination of friction

force, friction coefficient and friction

torque depending on the load)

Bullies tests

Efficiency test

Endurance tests (resource)

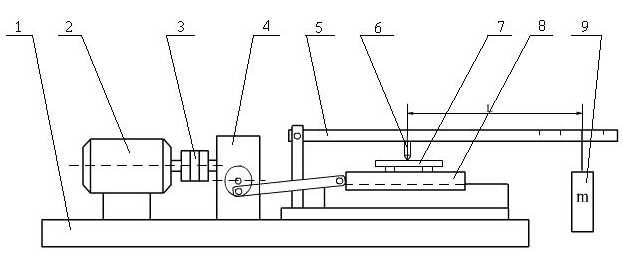

Slider type reciprocating friction machine

MTP 1/18

Efficiency test

Endurance tests (resource)

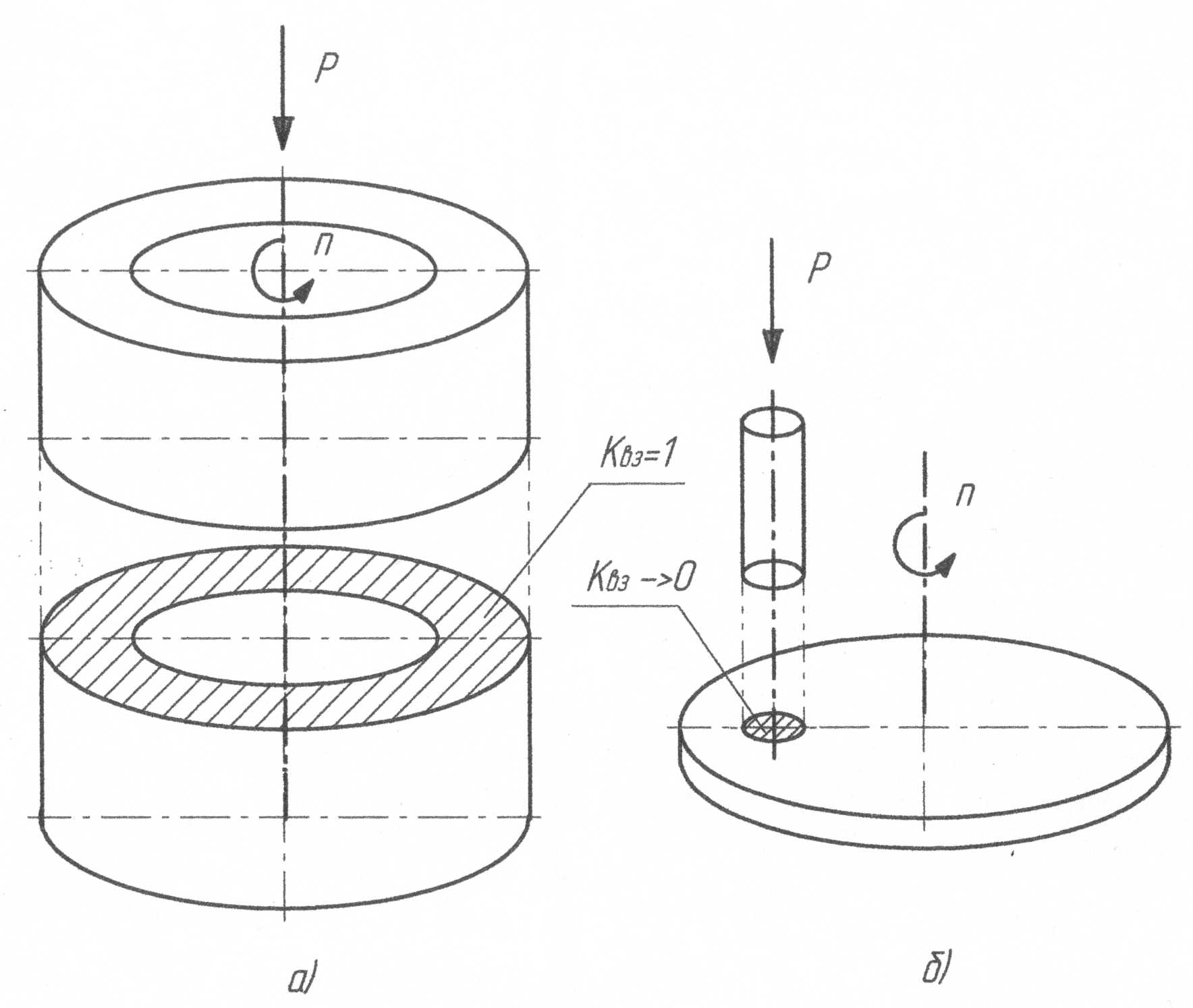

The stand of face friction 3030

modernized

Efficiency test

Endurance tests (resource)

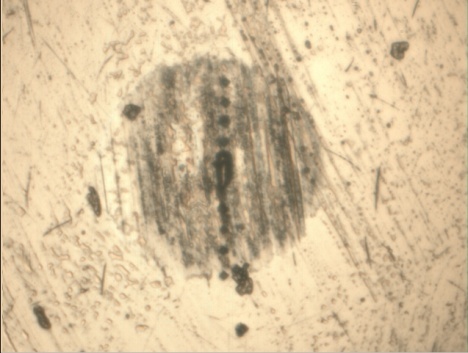

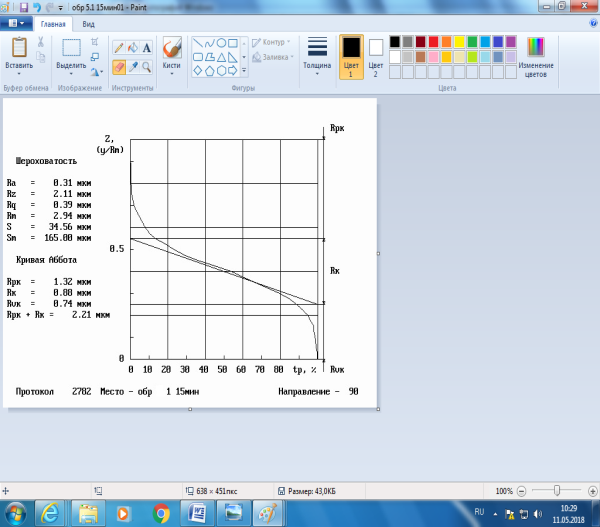

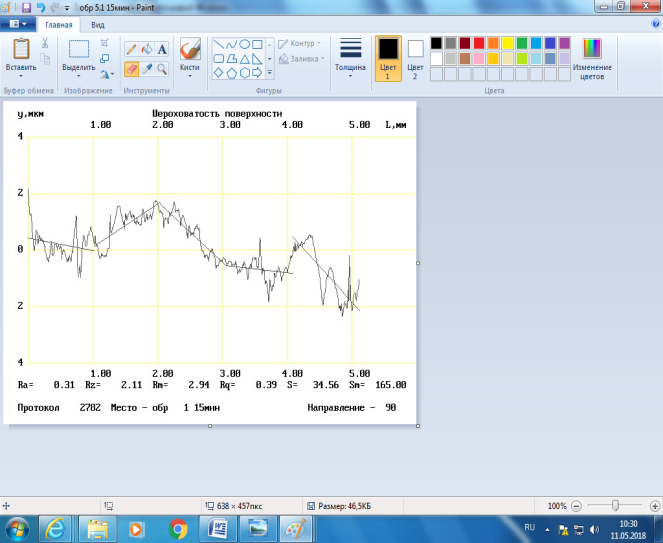

IVK Profile K-201

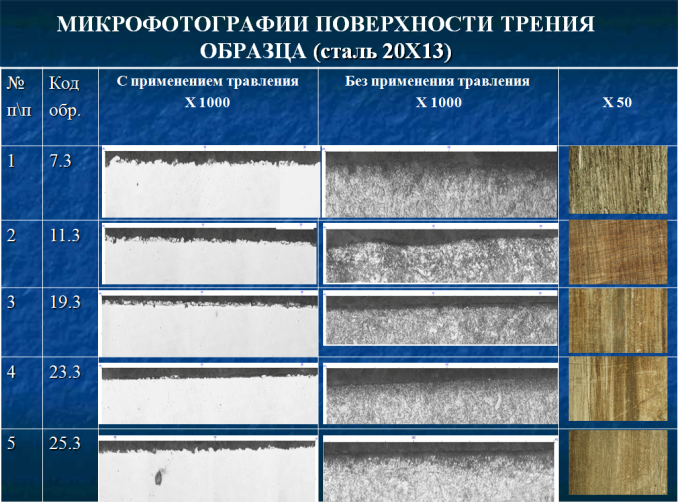

Microgeometry measurement of friction

surface

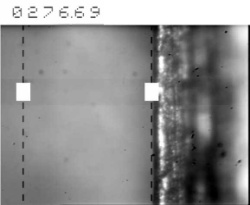

IVK Altami MBS-10

Measurement of friction surface wear

Friction machine four ball CTE-1

Testing of liquid and plastic lubricants

used for lubrication of rubbing surfaces

in order to determine the main

tribological characteristics of lubricants

in accordance with GOST 9490-75 “Liquid

and plastic lubricants. A method for

determining tribological characteristics

on a four-ball machine".